Construction Joint in Slabs

We often encounter construction joints during site construction. Maybe you might wonder what the purpose of construction joints is and what it is all about. A construction joint is one of the types of joints in site construction that can be located on walls and slabs. The most popular usage of construction joints is on suspended slabs. Literally, it is defined as a longitudinal cut in the slab during the concrete pouring process. It is termination on the slab during the concreting works. This is usually done in wide span areas of the slab being constructed by dividing the whole slab into a series of pour areas and it is intentionally applied to accommodate the easement of construction.

Before the start of concreting, the contractor shall submit the slab’s pouring layout to consultants which it is showing the sequence of concrete pouring to follow at the site. Here we can see that the slab pour layout drawings had a series of termination on different pour areas that is what we call the construction joints! The consultant will then be approved it to serve as a go signal to start the concreting. But, as a consultant what are the factors in facilitating the construction joints in slabs so we can give our CODE A approval? And for the contractor what are things that need to consider in proposing a construction joint in slabs so we cannot get a CODE C rejection? What does the code say about it? So many questions ask and need to be answered. In this article, we will one by one unlocks these questions and talk about the different design considerations of construction joints according to design codes and standards. They are as follows:

Constructability:

1. The positions/locations of construction joints shall be specified on a plan by the designer.

-Construction joint shall be provided preferably at a location where stresses are zero either 1/3 or at the end support

-Construction joint in girders shall be offset a distance of at least two times the width of intersecting beams, measured from the face of the intersecting beams.

2. Construction joint shall be cleaned and laitance removed before new concrete is placed.

3. The surface of the first pour should be intentionally roughened to increase the bond strength and to provide an aggregate interlock

Design Consideration:

Full structurally continuity is assumed in the design at a construction joint with the reinforcement being fully continuous across the joint. Since we are casting the slab at different times, shear transfer and a potential crack may occur and thus shear friction check should be performed.

A shear friction check shall be performed to address the possible failure by shear sliding on a plane as specified in ACI 318M-14.

The Design shear strength across the assumed shear plane shall satisfy:

[ACI 318_M-14, sect 22.9.3.1]

where: Φ=0.75 for shear

Vn: Nominal Shear (shear due to applied reinforcements)

Vu: Maximum Shear (maximum shear due to factored loadings)

- If shear-friction reinforcement is perpendicular to the shear plane, nominal shear strength across the assumed shear plane shall be calculated by:

[ACI 318M-14, sect 22.9.4.2]

where:

Avf: area of reinforcement crossing the assumed shear plane to resist shear (e.g. mesh reinforcement in case of a slab)

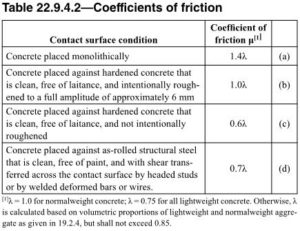

µ: coefficient of friction according to table 22.9.4.2. Refer to the image below as an excerpt on ACI 318M-14

Considering the equations above; if

then additional shear reinforcement is not required.

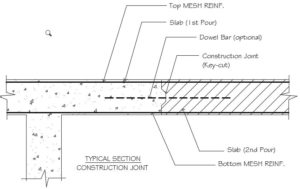

Below is the most common detail of the construction joint that is usually adopted on-site.

To further understand the above, refer to a worked example of a Shear Friction Check.

Reference Code: ACI 318M-14; BS8007

Tell us your thoughts. Leave your message in the comment section below. Feel free to share this article, subscribe to our newsletter, and follow us on our social media pages.

[DISPLAY_ACURAX_ICONS]