Shoring is used to support a structure to prevent a collapse. The most common shoring techniques that we encountered are during the early stage of construction which is an excavation. Shoring is intended to support a deep excavation to prevent the retained soil overturns and eventually cause a project mishap. Depending on the soil type, shoring support is usually provided when we need to support an excavation with at least 1.20-meter difference in levels from our gate level or the +/- 0.00 level. In construction, shoring is completely different from a retaining wall, as this is used only to retain the soil during the excavation and as far as the structural design is concern; it is not used primarily for the purpose of a retaining wall.

As a structural engineer, we should be able to know and decide which type of shoring suited the construction project that we are engaged at the early stage of design. To help you decide which is which, the author lists down its type and uses to help you narrow down the selection process. The five common types of shoring that we usually encountered in the construction project are:

1. H or I-Beam Shoring

H or I-Beam Shoring also known as soldier pile walls are the most common type of shoring that we usually encountered in a construction project. It is constructed by driving prefabricated steel I or H sections into the ground. Soil conditions may allow for the sections to be vibrated directly into the ground instead of the pre-drilling of the soil before installing the beam. The full wall is formed by installing a pre-cast concrete panel between the driven steel beams to construct the shoring walls.

H or I-Beam Shoring was used to support an excavation ranging from 1.2 to 5.0 meters deep or excavations equivalent to at least one basement and depending on the design, its toe length ranges from 10 meters to 12 meters depth from 0.00 levels. You can go beyond 5 meters provided that it is properly designed and calculated to sustain the given surcharge load along its outside perimeter.

To ensure safety in such deep excavations, trenching and excavation competent person training is crucial. This training equips personnel with the knowledge to identify potential hazards and implement the necessary precautions. It’s essential for maintaining stability and preventing accidents in challenging excavation projects.

I- Beam Shoring

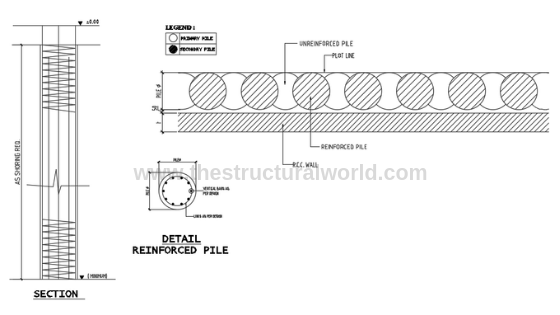

2. Secant Pile Shoring

Secant Pile Shoring was formed of intersecting two combinations of piles, with a “reinforced”, also called as secondary and “un-reinforced” or primary pile interlocking each other to form a continuous wall. A guide beam is constructed first prior to installation to keep the alignment in place. This is usually used in deep excavations. After casting the “primary” pile, the temporary casing is extracted while the concrete has not fully set and the heavy casing is then driven into the intervening pile location cutting into the fresh concrete of the adjacent pile. The “secondary” piles are then immediately drilled. The steel cages of the “secondary” pile are inserted and the structural concrete is poured to form a continuous wall.

A Guide Beam for Secant Pile Shoring

Secant Pies are the best choice to use when there is no room for open excavation or when space is limited because of an existing structure that was too close in proximity. In this case a surcharge loads due to the neighboring structure is considered in the design.

3. Contiguous Pile Shoring

Contiguous or Tangent Pile Shoring is composed of closely spaced piles wherein the faces of the piles are almost touching or tangent with each other. This is used in areas where water is not significant or the water pressure is very minimal. This is usually proposed in clay soils and can use to retain dry granular material or fills. Although water seepage between the gaps of the pile is more likely to occur when used in water-bearing granular soils, it can be prevented by grouting these gaps to form a water-tight retaining wall. This type of shoring is not recommended to use in high ground water table without dewatering works.

Construction of contiguous pile is very similar to that of the secant piles as prior to the installation, a guide beam should be constructed to serve as a guide for the contiguous wall to install in place.

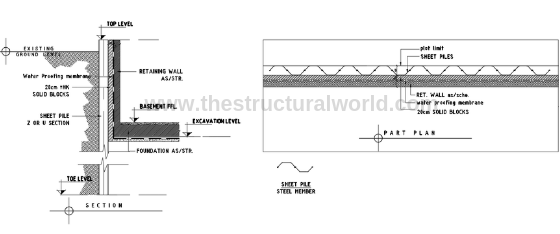

4. Sheet Piles

Although it can be used to retain soil to soil excavations, this type of shoring is bests to use when we need to isolate our excavation from the bodies of water specifically a creek, a pond or on a sea-side. It is commonly seen in a port and harbor construction. Similar to soldier piles, it can be constructed by driving prefabricated Z or U steel sections into the ground using a Vibro hammer. The full wall was formed connecting the Z or U steel sections or the sheet piles. Depending on the depth of excavation, the end of the sheet piles if not long enough can be welded together to reach the desired depth in the ground.

Sheet Piling Works

5. Diaphragm Walls

When the excavations are too deep for the type of shoring that is above mentioned above, diaphragm walls can be used. It is made of reinforced concrete designed primarily according to loads that needs to be resisted. It can be the element for a temporary or permanent retaining wall or both. For the deep excavation of the basement and tunnels, the diaphragm wall is the best option.

Other types such as cofferdams, raking shore, flying shoring, etc. are intended to use primarily according to its specialty. But the above are the most common type that we are using in the construction.

What do you think of the above article? Tell us your thoughts! Leave your message in the comment section below. Feel free to share this article, subscribe to our newsletter and follow us on our social media pages.

[DISPLAY_ACURAX_ICONS]

Shotcrete Works are can be a Shoring System ?

Shotcreting is a non-shoring system. It is usually applied after the shoring has been completed. It works as a plaster to even the surface for the waterproofing membrane to be fixed accordingly.

Shotcreting with soil nails is a shoring system. It apply on stable ground,soft rock and not deep applications.

Excellent post. I want to thank you for this informative read; I really appreciate sharing this great post. Keep up your work.An amazing article. It’s nice to read a quality blog post. I think you made some good points in this post.

I think the piles are well explained I have some property in Ireland suffering from sea erosion this were tackled beforefurther down the coast and is successful un fortuley local council don’t want to know and have installed 2klmtof seabes which is not working maybe you could come up with a solution all my neighbors are very distressed over the situation many thanks des o kelly

Pingback: The Saint Construction Update for October 23, 2020 | The Saint Construction Information

which type of shoring to be used if soil is weak and there is neighbour plot less than 5 meter from our plot limit

what is the type of shoring that a watertight system?

what is the difference between Secant and Contiguous shoring system?

Can screw jacks be used for water shoring?

Amazing, This article help to understand the basics of Shoring and types

very informative article you shared, Its clear basics of Shoring